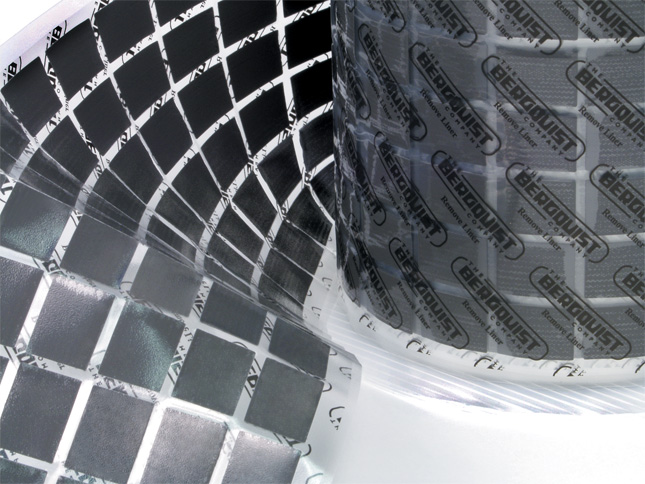

Features and advantages ·Thermal conductivity coefficient: 3.5W ·Thickness of gasket material: 0.508mm/3.175mm ·Flame retardant grade: V-O ·Continuous use temperature: -60 ℃+200 ℃ ·Insulation breakdown voltage: > 5000V ·Highly integrated and maintaining structural integrity with extremely low compressive stress ·Glass fiber reinforced puncture, shear, and tear resistance ·Non fiberglass options for reducing pressure required in applications

View More

Features and advantages ·Thermal conductivity coefficient: 3.0W ·Thickness of gasket material: 0.245mm/3.175mm ·Flame retardant grade: V-O ·Continuous use temperature: -40 ℃+125 ℃ ·Insulation breakdown voltage: > 6000V ·Silicon free formula

View More

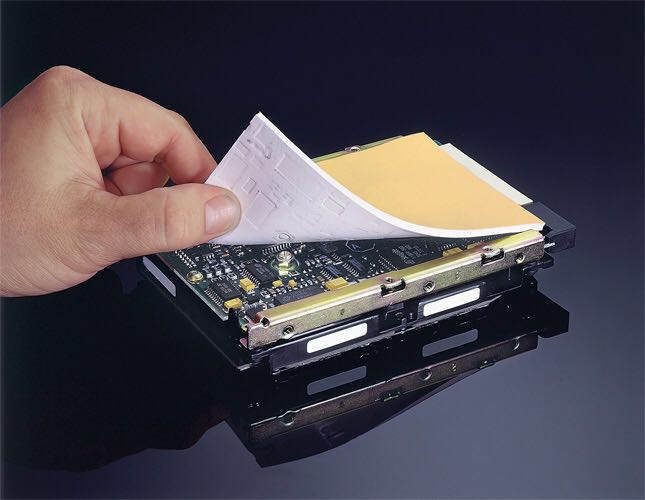

Features and advantages ·Thermal conductivity: 2 W ·Silicon free formula ·Minimum compressed set ·0.5mm film provides a non sticky surface ·The tacky side can be handled and placed easily

View More

Features and advantages ·Thermal conductivity: 1.5W ·Thermal impedance: 1.33 ℃ - in2/W (@ 30psi) ·Thickness of gasket material: 0.508mm -5.08mm ·Flame retardant grade: V-O ·Continuous use temperature:? 60℃+200℃ ·Insulation breakdown voltage: > 6000V ·Soft and low hardness

View More

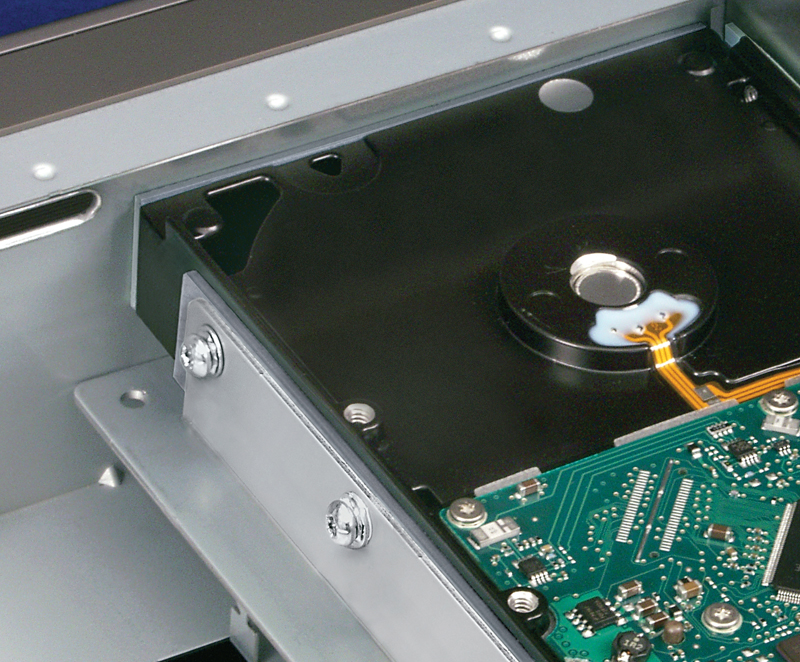

The GapPad 1500R gap pad has the same highly integrated, low modulus polymer, and glass fiber reinforced material treatment is easy to increase the allowable puncture, shear, and tear. The natural nails on both sides of the material allow for good compliance on the mating surface of the parts, further reducing thermal resistance.

View MoreProfessional service team of domestic thermal conductive material manufacturers

Pre sale

Pre sale1 、Our company can provide free sample test

2 、The sales staff will introduce the usage method and process in detail

3 、Provide a third-party authoritative test report

On sale

On sale1、Arrange production according to your specific needs

2、Strictly control product quality

3、Timely delivery

After sale

After sale1、If you need special technical support, our company can send someone to guide the use of the product

2、In the course of use, if there is any quality problem, our company will solve it on site at any time, and provide return and exchange services if necessary.

Demand-oriented customized exclusive product solutions

Product Advantages

Product Advantages Market Advantage

Market Advantage Technical Advantages

Technical Advantages Management Advantage

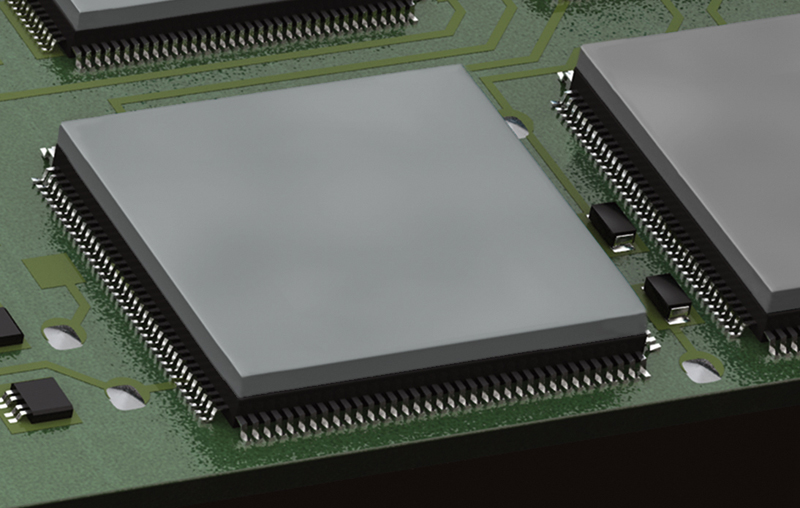

Management AdvantageThermal interface material specially designed for cooling electronic components

- Act quickly and indeed

- Improve full participation

- Value customer opinions

- Continuous improvement review

- Control environmental pollution

- Prevention training is prioritized

- Compliance with laws and regulations

- Continuous review and improvement

- satisfy customer's request

- Save energy resources

- Compliance with laws and regulations

- satisfy customer's request

- Continuous review and improvement

Professional service team of domestic thermal conductive material manufacturers

- 122021.08YHD thermal conductive silicone grease can effectively solve the heat dissipation problem of motor driver

The driver is a controller used to control the motor. Generally, the motor is controlled by position, speed and torque to achieve high-precision system positioning. Motor driver is widely used in industrial robots, NC machining and other automation equipment. It is an important part of modern operation control.

- 122021.08Two component thermal conductive potting adhesive is a good material to help electronic products solve the functions of heat dissipation and packaging and kill two birds with one stone

The two-component heat conductive potting adhesive can also be called AB heat conductive potting adhesive. Before curing, the heat conductive potting adhesive is liquid and has certain fluidity. It can flow into each gap for potting. After curing, an elastic adhesive layer is formed to give play to the effects of heat insulation, dust prevention and corrosion prevention, and resist high and low temperatures. Like ordinary adhesives, they will soften at temperatures above 100 ° and harden at low temperatures, but good thermal conductive adhesives can work for a long time at 150 ° ~ 200 ° without softening or fracture.

- 122021.08High thermal conductivity silicone grease can meet the heat dissipation requirements of LED driver

What we don't know is that the reason why the LED can work normally is closely related to the constant current provided by the driver itself in addition to heat dissipation. At present, the efficiency and power factor of most drivers are not particularly high. In detail, the driver is also a heat source. The temperature sensitivity of the components used in the driver is an important reference index affecting the operation of the driver. Therefore, in addition to the stable and reliable performance, our engineers also need to consider the upper limit working temperature and heat conduction and heat dissipation.

Professional service team of domestic thermal conductive material manufacturers

All my colleagues in the company wholeheartedly welcome your visit and guidance。