Many LED displays with advantages are applied in the market, and there are conspicuous LED products everywhere in the city. As we all know, LED display screen is afraid of heat and water. Heat has a fatal impact on the performance of LED display screen, which directly affects the stability of display screen use process and the service life of display screen. Therefore, in order to reduce the impact of heat on LED display screen, we need to know the heat dissipation characteristics of display screen, and then make a reasonable heat dissipation design scheme for display screen.

Poor heat dissipation will cause adverse effects on LED display, such as:

1、Impact on the service life of the screen; Under the environment of high temperature for a long time, the LED may decay faster, so that the screen body can not reach the designed service life at all, and the screen will be spent after a long time of use;

2、Poor or uneven heat dissipation may lead to uneven heat dissipation throughout the LED lamp, and the uneven attenuation speed of the three LED lamps of red, green and blue will lead to color deviation of the screen body. The brightness of LED lamps everywhere is different, which will certainly lead to the whole screen flower screen and other phenomena.

To solve the heat dissipation problem of LED display screen, we need to start from the following aspects:

1、Fan cooling:A fan with long service life and high efficiency is used inside the lamp shell to strengthen heat dissipation. This method has low cost and good effect. However, it is very troublesome to replace the fan, and it is not suitable for outdoor. This design scheme is relatively rare;

2、Surface radiation heat dissipation treatment:The surface of the lamp shell is treated with radiation heat dissipation. The simple thing is to apply radiation heat dissipation paint, which can bring the heat away from the surface of the lamp shell by radiation;

3、Aluminum radiating fin:This is a very common heat dissipation method. Aluminum heat dissipation fins are used as part of the shell to increase the heat dissipation area;

4、Aerodynamics:Convective air is produced by using the shape of the lamp shell, which is a low-cost way to strengthen heat dissipation;

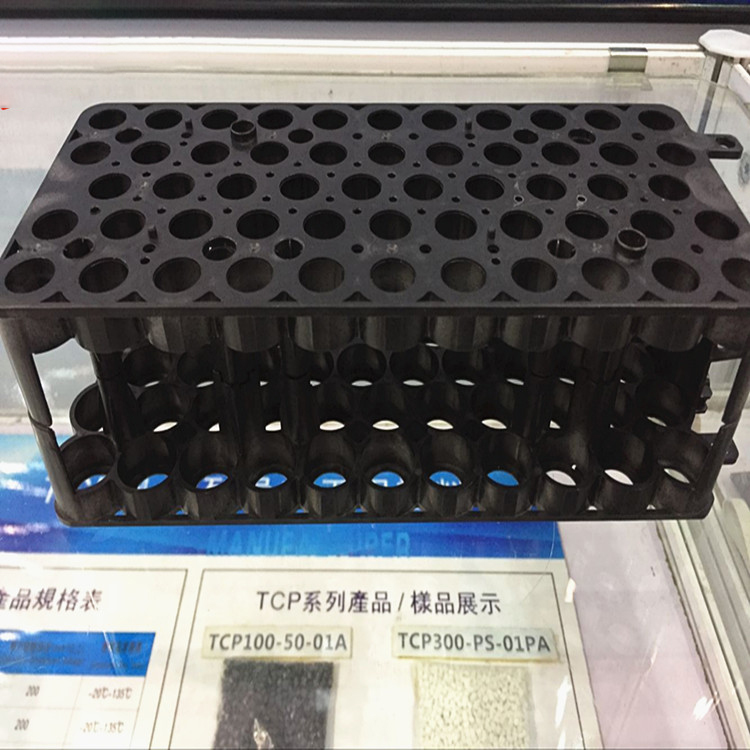

5、Heat conducting plastic shell:The plastic shell is filled with thermal conductive materials during injection molding to increase the thermal conductivity and heat dissipation capacity of the plastic shell. The shell and thermal conductivity exist together. The material that kills two birds with one stone is a good choice;

6、Liquid bulb:The transparent liquid with high thermal conductivity is filled into the bulb of the lamp body by using the liquid bulb packaging technology. This is a technology that uses the light emitting surface of LED chip to conduct heat and dissipate heat in addition to the reflective principle.

7、Heat dissipation of heat conduction pipe:Using the heat conduction tube technology, the heat is guided from the LED full-color display chip to the shell cooling fin, which is a common design in large lamps, such as street lamps.