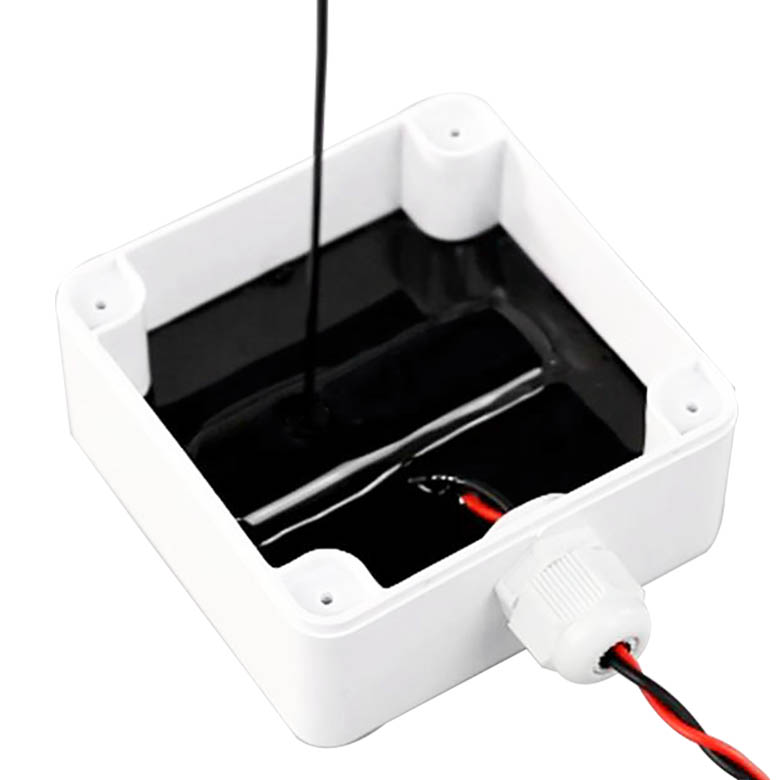

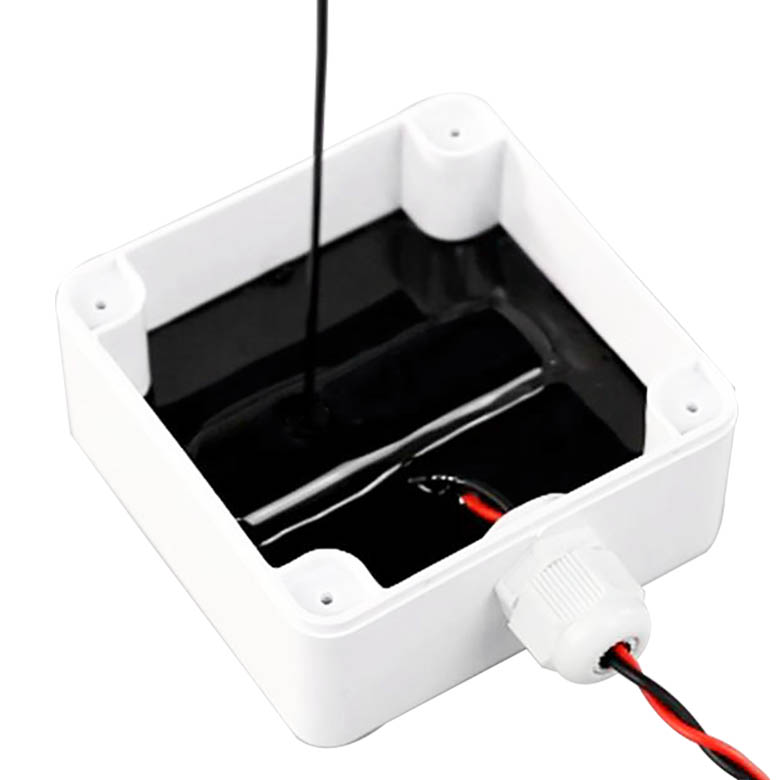

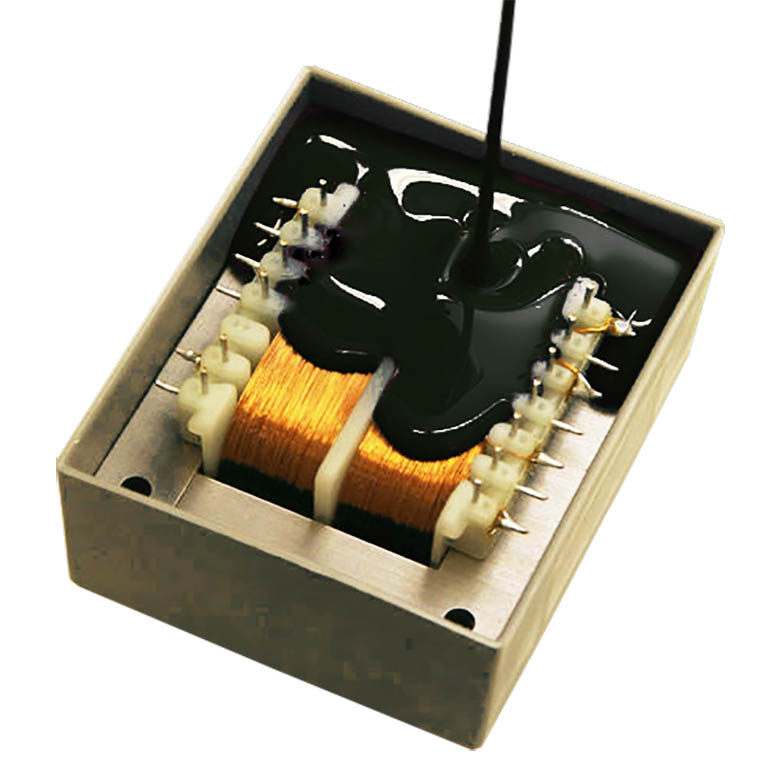

The two-component heat conductive potting adhesive can also be called AB heat conductive potting adhesive. Before curing, the heat conductive potting adhesive is liquid and has certain fluidity. It can flow into each gap for potting. After curing, an elastic adhesive layer is formed to give play to the effects of heat insulation, dust prevention and corrosion prevention, and resist high and low temperatures. Like ordinary adhesives, they will soften at temperatures above 100 ° and harden at low temperatures, but good thermal conductive adhesives can work for a long time at 150 ° ~ 200 ° without softening or fracture.

A good two-component heat conduction potting adhesive has high temperature resistance and better performance. After the adhesion is enhanced, it is bonded with the object to complete the sealing. It will not release toxic substances during use and will not pollute the environment. It is also widely used in new energy vehicles, medical and military industries, with good bonding effect on metals, glass, LCD pore sealing, coating and cover sealing, radiator assembly, thermal sensor potting, etc.

Heat conductive potting adhesive can strengthen the overall performance of electronic devices, improve the resistance to external impact and vibration, and improve the insulation properties between internal components and circuits, which is conducive to the miniaturization and lightweight of devices; Avoid direct exposure of components and circuits, and improve the waterproof and moisture-proof performance of devices. It has been widely used in electronic device manufacturing industry and is an indispensable and important heat conducting material in electronic industry. Heat conductive potting adhesive has excellent characteristics after complete curing in the packaging process, with low viscosity and strong infiltration, which can fill components and fill joints. The utility model has the advantages of convenient storage and long application period, and is suitable for large-scale automatic production lines. After complete curing, it has the properties of flame resistance, weather resistance, heat conduction, high and low temperature resistance, waterproof, etc.

When electronic products work, sometimes in the environment with large vibration, and the thermal conductive potting adhesive has certain elasticity, which can effectively improve the seismic performance of electronic products, and electronic products still maintain good performance. Moreover, it has the functions of dust prevention and heat dissipation. Ensuring the excellent service environment of electronic products is also very helpful to prolong the service life of electronic products.