Telephone:0755-33137976

Telephone:0755-33137976Co extruded conductive rubber

Product Description

Co extruded conductive silicone rubber material is composed of conductive rubber and non-conductive silica gel. It has excellent shielding efficiency, good water / gas sealing performance and corrosion resistance. The material can maintain long-term stability in a wide range of service temperature. Conductive silica gel mainly contains Ag / g, Ag / Al and Ni / C materials, which can meet the use requirements of customers through a variety of cross-sectional shape design.

Coextrusion material can save more space and cost, and achieve good air tightness and shielding effect at the same time. Non conductive rubber can provide excellent mechanical properties and reliability, and the conductive part can provide excellent shielding effect. And it can also provide more excellent compressibility during installation.

product features

▪ Excellent electromagnetic shielding effectiveness

▪ Good mechanical properties

▪ Excellent compression deformation performance provides better sealing effect

▪ Wide operating temperature range

▪ Excellent cost and space saving

typical applications

▪ Communication equipment

▪ Aerospace

▪ Sealing of outdoor equipment

▪ Outdoor

▪ Automotive electronics

technical parameter

| performance | standard | Conductive filler type | |||

| Ag/G | Ag/Cu | Ag/Al | Ni/C | ||

| Silicone color / conductive side color | / | Grey / yellow | Orange / yellow | Orange / yellow | Blue / Black |

| Silica gel density(g/cm3), ±0.25 | ASTM D792 | 1.2 | 1.2 | 1.1 | 1.2 |

| Conductive side density (g/cm3), ±0.25 | ASTM D792 | 2.0 | 2.2 | 2.1 | 2.1 |

| Silica gel hardness, Shore A, ±5 | ASTM D 2240 | 50 | 55 | 50 | 60 |

| Conductive side hardness, Shore A, ±5 | ASTM D 2240 | 65 | 80 | 65 | 70 |

| Tensile strength of silica gel, MPa, Min | ASTM D412 | 2.5 | 4.5 | 4.0 | 3.5 |

| Tensile strength of conductive side, MPa, Min | ASTM D412 | 1.5 | 1.0 | 1.0 | 1.5 |

| Elongation at break of silica gel side, %, Min | ASTM D412 | 200 | 300 | 300 | 150 |

| Elongation at break of conductive side, %, Min | ASTM D412 | 150 | 150 | 150 | 230 |

| Tear strength of silica gel side, kN/m, Min | ASTM D412 | 11 | 11 | 11 | 9 |

| Volume resistivity, Ω•cm | MIL-DTL-8352 C | 0.01 | 0.004 | 0.008 | 0.1 |

| Shielding efficiency, dB | |||||

| 200kHz(H-Field) | MIL-DTL-83528 C | 50 | 60 | 60 | 50 |

| 100MHz(E-Field) | MIL-DTL-83528 C | 100 | 115 | 115 | 100 |

| 500MHz(E-Field) | MIL-DTL-83528 C | 100 | 110 | 110 | 100 |

| 1GHz(Plane Wave) | MIL-DTL-83528 C | 90 | 110 | 105 | 90 |

| 2GHz(Plane Wave) | MIL-DTL-83528 C | 90 | 110 | 105 | 90 |

| 10GHz(Plane Wave) | MIL-DTL-83528 C | 80 | 110 | 100 | 90 |

| Operating temperature, ℃ | ASTM D1329 | -55~200 | -55~200 | -55~200 | -55~200 |

| Permanent compression deformation, % (100℃*70h*30%), Max | ASTM D395 | 10 | 10 | 10 | 17 |

| Flame retardant grade | UL 94 | HB | HB | HB | HB |

| workmanship | / | Co-extrusion | Co-extrusion | Co-extrusion | Co-extrusion |

Standard section shape*

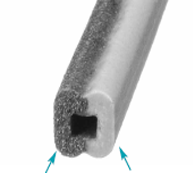

Conductive side Non conducting side |

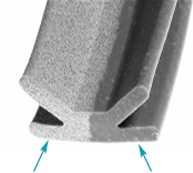

Conductive side Non conducting side |

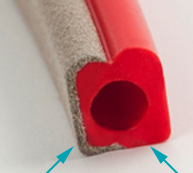

Conductive side Non conducting side |

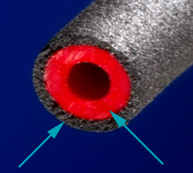

Conductive side Non conducting side |